Summit Nanotech Validates Sorbent with Industry-Leading Reliability and Performance

CALGARY, Alberta, Sept. 30, 2025 (GLOBE NEWSWIRE) -- Summit Nanotech (“Summit”), a global leader in direct lithium extraction (DLE) technology, today announced breakthrough results validating the reliability and performance of its proprietary sorbent, eLivate™, across a wide range of brine compositions in Chile, Argentina, and the Smackover region of the United States.

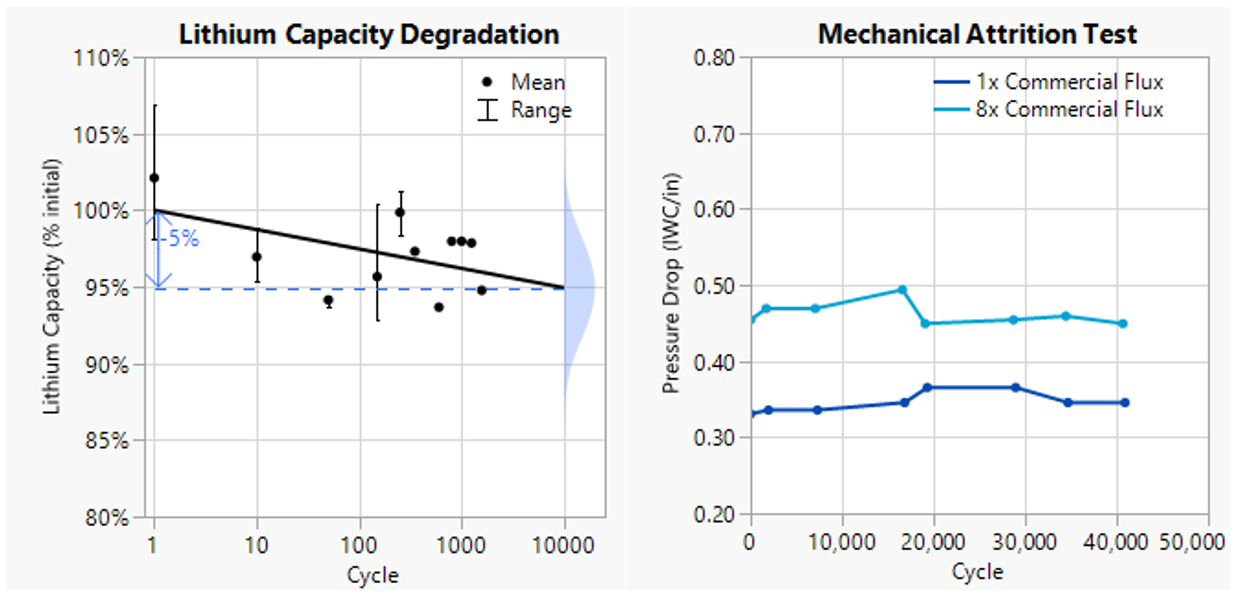

Results from Summit’s advanced reliability engineering program confirm that its eLivate™ sorbent can achieve 10,000 operating cycles with 5% degradation, while maintaining >98% lithium recovery, >95% impurity rejection, and DLE-specific water use below 10 m³/tonne LCE. These results support Summit’s projection of a commercial sorbent lifespan of >5-8 years.

A New Standard for Sorbent Reliability

All DLE sorbents have unique performance and durability. Recognizing that DLE project owners require robust, evidence-based validation of sorbent longevity, Summit developed a comprehensive in-house reliability engineering program to accurately forecast sorbent lifespan. This program includes two custom-built testing platforms designed to simulate chemical and mechanical stress under real-world conditions, enabling precise performance modeling and continuous improvement.

To validate lifespan projections, Summit ran 1500 cycles of adsorption-desorption through its reliability testing program, utilizing brine from a South American salar. Summit also ran mechanical attrition tests, subjecting sorbent to the mechanical impact of on-off switching at normal and at 8X process flowrates. Each of the two conditions were operated through 40,000 cycles with no measurable change in pressure drop. Projections will soon be bolstered by additional accelerated life tests (ALT) that demonstrate full lifecycle results and multi-factorial contaminant effects.

This reliability advantage translates into:

- Lower operating costs – Reduced replacement frequency lowers OpEx.

- Lower capital costs – Higher sorbent efficiency enables the use of smaller DLE columns.

- Reduced downtime– Stable recovery rates and minimal downtime enhance long-term output and IRR.

- Sustainability benefits – Extended sorbent life minimizes waste and resource consumption, reducing environmental impact.

"These results give developers confidence that Summit can deliver DLE projects at the lowest levelized cost of lithium, with best-in-class reliability,” said Jeremy Patt, Chief Technology Officer at Summit. “It demonstrates not only the strength of our technology, but also the rigor we have applied to scaling it for commercial success."

Strategic Advancements in DLE

This milestone builds on Summit’s recent achievements:

- Successful operation of Summit’s in-field demonstration plant in Chile since May, supplied entirely with its proprietary eLivate™ sorbent.

- Construction of a new in-house demonstration plant at the company’s Santiago facility. Fully operational in January, this plant provides comprehensive validation for full-scale commercial design that is customized for the particular brine asset. Customers receive detailed commercial design reports including capex and opex for their project, accelerating the path to final investment decision (FID).

- Validation of Summit’s sorbent and process technology across a wide range of brine assets from Chile, Argentina, and Smackover.

With reliability and performance validated, Summit is finalizing a scale production agreement with a leading, global chemical manufacturer. Summit's partner will be able to deliver sorbent quantities over 1000 tonnes per year.

DLE Done Right

Summit’s technology is setting the pace for DLE, consistently outperforming alternatives in reliability, efficiency, and economics. Its modular system and high-performance sorbent, engineered in North America, produce high-purity lithium from brines in Chile, Argentina, and the United States, with industry-leading water efficiency.

Its in-house demonstration plant will begin processing customer brines in January 2026, supporting commercial projects over 5 kt/y LCE and offering the full range of plant capacities demanded by the market. Companies interested in validating their lithium assets are encouraged to contact Summit to secure participation.

Media Contact

Kristen Gray

Manager, Marketing and Communications

kristen.gray@summitnanotech.com

Sales Contact

Rodrigo Mery

Manager, Business Development

rodrigo.mery@summitnanotech.com

An infographic accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/5a7831f0-1b4d-42cf-bbd7-5166d60bb51b

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.